Ekujuleni kwe-supply chain, ezinye izangoma ziphendula isihlabathi sibe amadiski e-silicon crystal akhiwe ngedayimane, abalulekile kulo lonke uchungechunge lokunikezwa kwe-semiconductor. Bayingxenye yochungechunge lokunikezwa kwe-semiconductor okwandisa inani "le-silicon sand" cishe izikhathi eziyinkulungwane. Ukukhanya okuncane okubona ogwini kuyi-silicon. I-Silicon iyikristalu eyinkimbinkimbi enokuqina kanye nensimbi eqinile (izakhiwo zensimbi nezingezona ezensimbi). I-silicon ikhona yonke indawo.

I-silicon iyinto yesibili evame kakhulu Emhlabeni, ngemva kwe-oksijini, futhi iyinto yesikhombisa evame kakhulu endaweni yonke. I-silicon i-semiconductor, okusho ukuthi inezinto zikagesi phakathi kwama-conductor (njengethusi) nama-insulators (njengengilazi). Inani elincane lama-athomu angaphandle esakhiweni se-silicon lingashintsha ngokuyisisekelo ukuziphatha kwalo, ngakho-ke ubumsulwa be-silicon yebanga le-semiconductor kufanele buphakame ngendlela emangalisayo. Ubuncane bokuhlanzeka okwamukelekayo kwe-silicon yebanga le-elekthronikhi ngu-99.999999%.

Lokhu kusho ukuthi i-athomu eyodwa kuphela engeyona i-silicon evunyelwe kuwo wonke ama-athomu ayizigidi eziyizinkulungwane eziyishumi. Amanzi okuphuza amahle avumela ama-molecule angewona amanzi ayizigidi ezingama-40, ahlanzekile ngokuphindwe izikhathi eziyizigidi ezingama-50 kune-silicon yebanga le-semiconductor.

Abakhiqizi be-silicone wafer abangenalutho kumele baguqule i-silicon ehlanzekile ibe yizinhlaka eziphelele zekristalu eyodwa. Lokhu kwenziwa ngokwethula ikristalu kamama ongayedwa ku-silicon encibilikisiwe ezingeni lokushisa elifanele. Njengoba amakristalu endodakazi entsha eqala ukukhula eduze kwekristalu kamama, i-silicon ingot yakheka kancane isuka ku-silicon encibilikisiwe. Inqubo ihamba kancane futhi ingase ithathe iviki. I-silicon ingot eqediwe inesisindo esingamakhilogremu ayi-100 futhi ingenza ama-wafer angaphezu kuka-3,000.

Ama-wafers asikwa abe izingcezu ezincane kusetshenziswa ucingo lwedayimane olucolekile kakhulu. Ukunemba kwamathuluzi okusika i-silicon kuphezulu kakhulu, futhi opharetha kufanele bahlale begadiwe, noma bazoqala ukusebenzisa amathuluzi ukwenza izinto eziwubuwula ezinweleni zabo. Isethulo esifushane sokukhiqizwa kwama-silicon wafers senziwe lula kakhulu futhi asiniki ikhredithi ngokugcwele iminikelo yezihlakaniphi; kodwa kuthenjwa ukuthi izohlinzeka ngesizinda sokuqonda okujulile kwebhizinisi le-silicon wafer.

Ubudlelwano bokuhlinzeka nokufunwa kwama-silicon wafers

Imakethe ye-silicon wafer ilawulwa izinkampani ezine. Isikhathi eside, imakethe ibilokhu ikubhalansi ethambile phakathi kokuhlinzeka nokufunwa.

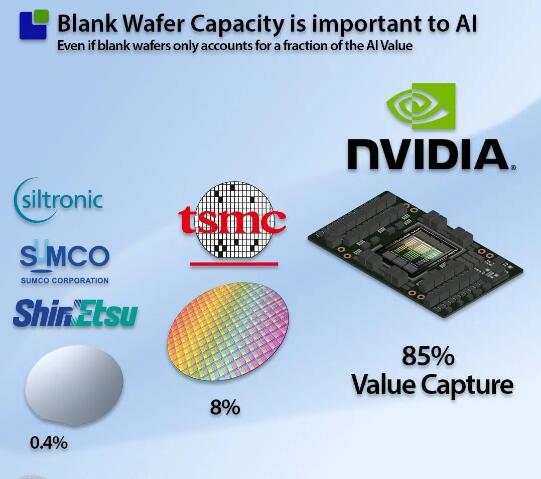

Ukwehla kokuthengiswa kwe-semiconductor ngo-2023 kuholele ekutheni imakethe ibe sesimweni sokugcwala ngokweqile, okubangele ukuthi uhlu lwangaphakathi nangaphandle lwabakhiqizi bama-chip lube phezulu. Nokho, lesi yisimo sesikhashana nje. Njengoba imakethe isimama, imboni maduze izobuyela emaphethelweni omthamo futhi kufanele ihlangabezane nesidingo esengeziwe esilethwe uguquko lwe-AI. Ushintsho olusuka ekwakhiweni komdabu okusekelwe ku-CPU ukuya kukhompyutha esheshayo luzoba nomthelela kuyo yonke imboni, njengoba Nokho, lokhu kungase kube nomthelela kumasegimenti enani eliphansi lomkhakha we-semiconductor.

Izakhiwo ze-Graphics Processing Unit (GPU) zidinga indawo ye-silicon eyengeziwe

Njengoba isidingo sokusebenza sikhula, abakhiqizi be-GPU kumele banqobe imikhawulo ethile yedizayini ukuze bathole ukusebenza okuphezulu kuma-GPU. Ngokusobala, ukwenza i-chip ibe nkulu kuyindlela eyodwa yokufeza ukusebenza okuphezulu, njengoba ama-electron engathandi ukuhamba amabanga amade phakathi kwama-chips ahlukene, okukhawulela ukusebenza. Kodwa-ke, kunomkhawulo osebenzayo wokwenza i-chip ibe nkulu, eyaziwa ngokuthi "umkhawulo we-retina".

Umkhawulo we-lithography ubhekisela kusayizi omkhulu we-chip ongavezwa esinyathelweni esisodwa emshinini we-lithography osetshenziswa ekwenzeni i-semiconductor. Lo mkhawulo unqunywa ubukhulu bendawo kazibuthe yobukhulu bemishini ye-lithography, ikakhulukazi isitebhisi noma isithwebuli esisetshenziswa enqubweni ye-lithography. Ngobuchwepheshe bakamuva, umkhawulo wemaski uvamise ukuzungeze amamilimitha-skwele angama-858. Lo mkhawulo kasayizi ubaluleke kakhulu ngoba unquma indawo ephezulu engenziwa iphethini ku-wafer ekuchazweni okukodwa. Uma i-wafer inkulu kunalo mkhawulo, kuzodingeka ukuchayeka okuningi ukuze iphethini ngokugcwele i-wafer, engakwazi ukukhiqizwa ngobuningi ngenxa yobunkimbinkimbi kanye nezinselele zokuqondanisa. I-GB200 entsha izowunqoba lo mkhawulo ngokuhlanganisa ama-chip substrates amabili nokulinganiselwa kosayizi wezinhlayiyana ibe yi-silicon interlayer, yakhe i-super-particle-limited substrate enkulu ngokuphindwe kabili. Eminye imikhawulo yokusebenza inani lenkumbulo kanye nebanga laleyo nkumbulo (okungukuthi i-memory bandwidth). Izakhiwo ezintsha ze-GPU zinqoba le nkinga ngokusebenzisa inkumbulo enqwabelene yomkhawulokudonsa ophezulu (HBM) efakwe ku-silicon interposer efanayo nama-chips amabili e-GPU. Ngokombono we-silicon, inkinga nge-HBM ukuthi indawo ngayinye ye-silicon iphindwe kabili kune-DRAM yendabuko ngenxa yokuxhumana okuphezulu okuhambisanayo okudingekayo kumkhawulokudonsa ophezulu. I-HBM iphinde ihlanganise i-chip yokulawula okunengqondo kusitaki ngasinye, ikhulise indawo ye-silicon. Ukubala okunzima kukhombisa ukuthi indawo ye-silicon esetshenziswa ku-2.5D GPU ye-architecture iphindwe izikhathi ezingu-2.5 kuya kwezingu-3 kunezobuciko bomdabu be-2.0D. Njengoba kushiwo ngaphambili, ngaphandle uma izinkampani ezisunguliwe zilungiselelwe lolu shintsho, umthamo we-silicon wafer ungase uqine kakhulu futhi.

Umthamo wesikhathi esizayo wemakethe ye-silicon wafer

Umthetho wokuqala kwemithathu yokukhiqiza i-semiconductor ukuthi imali eningi idinga ukutshalwa uma inani elincane lemali litholakala. Lokhu kungenxa yemvelo yomjikelezo wemboni, futhi izinkampani ze-semiconductor zinesikhathi esinzima ukulandela lo mthetho. Njengoba kuboniswe esithombeni, abakhiqizi abaningi be-silicone wafer bawubonile umthelela walolu shintsho futhi bacishe baphinda kathathu isamba sezindleko zabo zenyanga ngekota ezingxenyeni ezimbalwa ezedlule. Naphezu kwezimo zemakethe ezinzima, lokhu kusenjalo. Okuthakazelisa nakakhulu ukuthi lo mkhuba usunesikhathi eside uqhubeka. Izinkampani ze-Silicon wafer zinenhlanhla noma zazi okuthile abanye abangakwazi. I-semiconductor supply chain ingumshini wesikhathi ongabikezela ikusasa. Ikusasa lakho lingase libe elomunye umuntu. Nakuba singazitholi izimpendulo ngaso sonke isikhathi, cishe njalo sithola imibuzo ebalulekile.

Isikhathi sokuthumela: Jun-17-2024